Since I learned how to make the short row heel, with all its variations, I have been fascinated with the concept. It is not at all unusual for someone to find me casting on a number of stitches on to a DPN, to try out a new idea on how to use them. Recently I have been charting my short row shapes, which gives me a clearer picture of the end product, and the opportunity to change the stitch groupings as needed to get the desired affect I want.

For example –

Even though the chart clip is small, viewing it from the bottom up, you can see the angle of each side. This chart leaves a pair of stitches on the needle with each turn. Rows 7 and 8, close the gaps and complete the shape.

In this chart, groupings of three stitches are left on each end before the turn, thus changing the angle of ascent.

In the chart above, I have combined groups of 2,3 and 4 stitches to create a more rounded shape. Here, rows 9-10 close the gaps and complete the shapes. The possibilities are endless.

How do I close my gaps? I pick up the stitch that looks like a “collar” around the slipped stitch of the previous row, place it on the left needle, and knit or purl it together with the slipped stitch.

What does that look like?

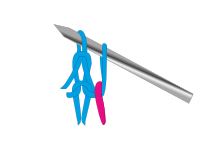

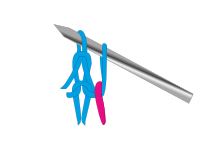

Above, is an illustration of how it looks after you turn, slip one stitch and knit the next. I have highlighted the “collar” in pink. You will notice that is actually is the stitch below the slipped stitch that forms this “collar.” You will also notice that it leans slightly toward the left, as it is being pulled over with the slipped stitch.

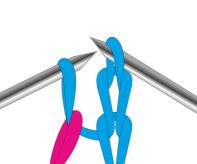

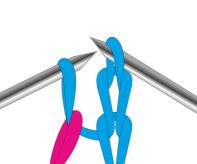

This illustration shows you the slipped stitch turn on the purl side. Here again, the stitch(collar) leans to the left a bit.

What do I do with the “collars?”

I haven’t made a video of this yet, but Cat Bourdhi has, in her Sweet Tomato heel demo on YouTube. But that aside, I have drawn some illustrations to make my point.

When you have a “collar” (pink) around the stitch just before the gap as in the illustration above, you lift the “collar” (pink) up and onto the left needle, then knit it together with the slipped stitch.

This process closes the gap. From here you can knit the next stitch or stitches of the next grouping until you come to the next “stitch collar.” This works the same on the purl side as well. You will find it is a very smooth transition. Another advantage of experimenting with the various stitch groupings is that you can shape your toe caps (see my More Toes Tutorial) as desired. You can combine the various groupings with the single stitch turns normally used in the short row heel ( a 90 degree turn) to finish the cap before picking up your stitches off the provisional cast on to start knitting in the round. For those of you who already use my method of short row heel, you will recognize this as the SPR. The only difference is that you are lifting the loop and knitting or purling it with the loop to its immediate left (the slipped st).

I will soon be posting the complete tutorial as a PDF. So check back soon. In the meantime, try some different shapes of your own. Also don’t forget to check out the “Sweet Tomato Heel” tutorial on YouTube.

Now that I have completely confused you , I bid you happy knitting!

KT

Read Full Post »